Control and Power Reeling Cables 0.6 / 1 (1.2) kV

Applications

Cables with reinforced polyurethan sheath, especially designed for reeling applications.

Due to high mechanical properties of PUR, Buflex cables could be used in hard conditions as quarries, mines …

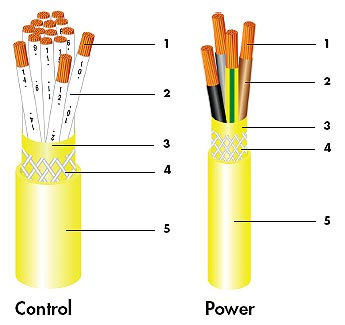

Design

1. Conductor

Flexible plain copper, class 5 IEC 60228

Flexible plain copper, class 5 IEC 60228

2. Insulation

XLPE

3. Filler + Inner Sheath

4. Reinforcement

Anti twist element

5. Outer sheath

PUR

Colour: yellow

Marking

BUFLEX DGR – 0.6/1 kV

Number of cores – cross-section

NEXANS – year – week

Cores Identification

Control: white with printed numbers

Power:

4 cores: black – brown – grey – green/yellow (3 earth cores for sizes ≥ 25 mm2)

5 cores: black – brown – grey – blue – green/yellow

Mechanical properties

| Max. tensile load | 20 N/mm2 of copper cross section |

| Tests | Bending test, torsional test |

| Reeling speed | up to 120 m/min (for higher speed contact us) |

Chemical properties

Oil resistant.

For outdoor applications. Moisture, UV and ozone resistance.

Electrical and Thermal properties

| Nominal voltage | Uo/U | 0.6/1 kV |

| Maximum operating voltage in AC systems | Um | 1.2 kV |

| Test voltage: | ||

| – Power | 3.5 kV in AC | |

| – Control | 2.5 kV in AC | |

| Current rating (A) | see electrical characteristics page 3.2 B | |

| Max. temperature at the conductor : | ||

| – in service | + 90 °C | |

| – under short circuit conditions | + 250 °C | |

| Max. surface temperature : | ||

| – fixed installation | – 40 °C up to + 80 °C | |

| – mobile operation | – 30 °C up to + 80 °C | |

BUFLEX® DGR

| Number of cores and nominal cross-section |

Outer diameter | Weight approx. |

Max. tensile load |

||

| (mm2) | Min. (mm) | Max. (mm) | (kg/km) | (N) | |

| POWER | 4 G 2.5* | 10 | 11.5 | 180 | 200 |

| 4 G 4* | 11.5 | 13 | 260 | 320 | |

| 4 G 6* | 13 | 14.5 | 370 | 480 | |

| 4 G 10* | 15.5 | 17 | 580 | 800 | |

| 4 G 16* | 19.5 | 21.5 | 920 | 1,280 | |

| 3 x 25 + 3 G 6* | 23.5 | 25.5 | 1,240 | 1,800 | |

| 3 x 35 + 3 G 6* | 27 | 29.5 | 1,640 | 2,400 | |

| 3 x 50 + 3 G 10* | 30 | 32.5 | 2,240 | 3,600 | |

| 3 x 70 + 3 G 16* | 35 | 37.5 | 3,100 | 5,100 | |

| 3 x 95 + 3 G 16* | 39 | 42 | 3,890 | 6,600 | |

| 3 x 120 + 3 G 25* | 44 | 47 | 5,080 | 8,700 | |

| 3 x 150 + 3 G 25* | 49 | 52.5 | 6,160 | 10,500 | |

| 3 x 185 + 3 G 35 | 54.5 | 58.5 | 7,680 | 13,200 | |

| 3 x 240 + 3 G 50 | 60.5 | 64.5 | 9,870 | 17,400 | |

| 3 x 300 + 3 G 50 | 68.5 | 72.5 | 12,300 | 21,000 | |

| 5 G 2.5 | 11 | 12.5 | 220 | 250 | |

| 5 G 4 | 13 | 14.5 | 320 | 400 | |

| 5 G 6* | 15 | 16.5 | 450 | 600 | |

| 5 G 10 | 18 | 20 | 700 | 1,000 | |

| 5 G 16* | 22 | 24 | 1,100 | 1,600 | |

| 5 G 25 | 27 | 29.5 | 1,550 | 2,500 | |

| 5 G 35 | 31 | 33.5 | 2,050 | 3,500 | |

| CONTROL | 7 x 1.5 | 11.5 | 13 | 210 | 210 |

| 12 x 1.5 | 16 | 17.5 | 330 | 360 | |

| 18 x 1.5 | 16 | 17.5 | 410 | 540 | |

| 24 x 1.5 | 19 | 21.5 | 680 | 720 | |

| 36 x 1.5 | 22 | 24 | 900 | 1,080 | |

| 7 x 2.5 | 12.5 | 14 | 30 | 350 | |

| 12 x 2.5* | 18.5 | 20.5 | 610 | 600 | |

| 18 x 2.5* | 18.5 | 20.5 | 740 | 900 | |

| 24 x 2.5 | 22.5 | 24.5 | 1,050 | 1,200 | |

| 36 x 2.5* | 25 | 28 | 1,430 | 1,800 | |

| 42 x 2.5 | 27 | 29.5 | 1,500 | 2,100 | |

| 26 x 2.5 + (4 x 2.5)C* | 24.5 | 27 | 1,260 | 1,500 | |