Strength members in flexible cables could be placed in different arrangements:

Strength members in flexible cables could be placed in different arrangements:

- outside the cable

- elements (e.g. braid) between inner and outer sheaths

- in flat cables besides the cores

- in the center of cable.

The effects of a strength member are:

- to take over a part of the pulling force to reduce the mechanical stress from the copper conductor.

It ensures compliance with VDE 0298 standard part of 15 N/mm2 (referring to the copper cross-section of the main cores).

- to reduce the risk of a corkscrew-effect. That would be caused by turning off the stranding from the cores and simultaneous turning on in an other part of the cable length.

- to reduce the risk of torsion in a cable by a reduction of the tensile force of the stranding conductor.

The most common strength members are:

- Steel rope

- Polyamid/ polyester ropes

- Aramid/ kevlar yarns

- Natural fiber e.g. sash line

- Coated E-glass

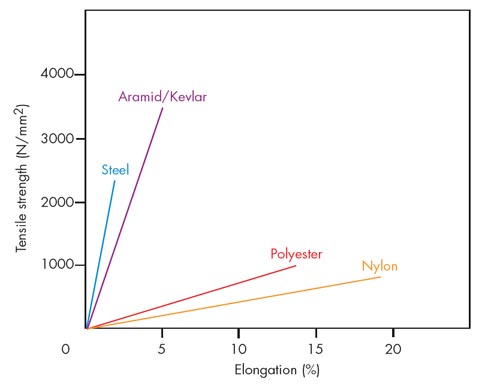

Depending on the detailed application of the flexible handling cable, physical characteristics like elongation [%], elastic stability (N/mm2), breaking load (kN), laying types and reversed bending properties of the different strength members must be analysed.

Other integrated elements like reinforcement braids used as strength member, relieve the conductor after stress application. The strength members used by Nexans relieve the conductor instantaneously with stress application.