Reeling Cables with integrated Optical Fibers 1.8/3 (3.6) kV up to 18/30 (36) kV

Reeling Cables with integrated Optical Fibers 1.8/3 (3.6) kV up to 18/30 (36) kV

Applications

Flexible reeling cable for energy supply and data transmission. Especially for high and extreme mechanical stress, e.g. torsional stress and high reeling speed. For deflection into different planes. Also usable for festoon systems, open-cast and underground mining.

Design

Main applications: Ship to Shore Cranes (STS), Rail Mounted Gantry Cranes (RMG), Ship Unloader, Stacker Reclaimer and other heavy mobile equipment.

Marking

Marking

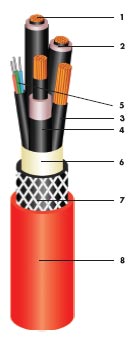

| 1. Conductor | Flexible, plain copper, “FSC” better than IEC 60228 class 5 |

| 2. Insulation | Inner semi-conductive layer New special insulation compound “RHEYCLEAN” based on EPDM, better than DIN VDE 207 part 20. Outer semi-conductive layer,“RHEYSTRIP”, easy strip design |

| 3. Protective earth conductor | Flexible, plain copper, “FSC” better than IEC 60228 class 5 |

| 4. Semi-conductive layer | 5. Optical fibre Fiber diameter 9/125 μm 50/125 μm 62.5/125 μm |

| 6. Inner sheath | Special synthetic rubber, better than GM1b |

| 7. Reinforcement | Synthetic threads with very high tensile strength as a protection against twist stress and pressure loads |

| 8. Outer sheath | New special sandwich construction for an optimum of flexibility, abrasion resistance and heavy load, special rubber compound |

| Colour: | Red |

Marking

RHEYFIRM(RTS) (N)TSCGEWTOEUS OFE

Number of cores – cross-section Voltage – NEXANS – year

Core Identification

Split protective earth cores are integrated in two of the three interstices. The optical fiber element is accommodated in the third. Length of lay is optimized for the different applications

Standards

In line with

DIN VDE 0250 part 813

DIN VDE 0295

DIN VDE 0298

DIN VDE 0472

prEN 50363

DIN VDE 0888

Mechanical properties

| Tensile stress of the conductor | static | 15 N/mm2 |

| dynamic | 30 N/mm2 | |

| Bending radii | according to DIN VDE 298, | |

| Tests | alternating/reversed and roller bending test, | |

| torsional resistance test | ||

| Reeling speed | up to 190 m/min (for higher speed contact us) |

Chemical properties

Oil resistant.

For indoor and outdoor applications. Moisture, UV and ozone resistance.

Flame-retardant according to IEC 60 332 part 1.

Electrical, Optical and Thermal properties

| Nominal voltage | Uo/U | 1.8/ 3 kV to 18/30 kV |

| Maximum operating voltage in AC systems | Um | 1.2 x U |

| Maximum operating voltage in DC systems | Vm | 1.8 x U |

| Test voltage | 11 to 45 kV in AC | |

| 27.5 to 107.5 kV in DC | ||

| Current rating (A) | according to DIN VDE 0298 part 4, | |

| see electrical characteristics page 3.2 B | ||

| Max. temperature at the conductor: | ||

| – in service | + 90 °C | |

| – under short-circuit conditions | + 250 °C | |

| Max. surface temperature: | ||

| – fixed installation | – 50 °C up to + 80 °C | |

| – mobile operation | – 35 °C up to + 80 °C | |

| Number of cores and nominal cross-section |

Outer diameter | Weight approx. |

Tensile strength |

|

| (mm2) | Min. (mm) | Max. (mm) | (kg/km) | (N) |

| 1.8/3 (3.6) kV | ||||

| 3 x 25 + 2 x 25/2 + OFE | 31 | 34 | 1,820 | 3,000 |

| 3 x 35 + 2 x 25/2 + OFE | 34 | 37 | 2,280 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE | 38 | 41 | 2,850 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE | 43 | 46 | 3,830 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 49 | 51 | 4,810 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 54 | 57 | 6,000 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 57 | 60 | 7,040 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 62 | 65 | 8,430 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 69 | 72 | 10,590 | 14,400 |

| 3.6/6 (7.2) kV | ||||

| 3 x 25 + 2 x 25/2 + OFE* | 39 | 42 | 2,310 | 3,000 |

| 3 x 35 + 2 x 25/2 + OFE* | 42 | 45 | 2,850 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE* | 46 | 49 | 3,480 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE* | 49 | 52 | 4,380 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 55 | 58 | 5,400 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 58 | 61 | 6,470 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 64 | 67 | 7,850 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 68 | 71 | 9,120 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 73 | 76 | 11,150 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 80 | 84 | 13,490 | 18,000 |

| 6/10 (12) kV | ||||

| 3 x 25 + 2 x 25/2 + OFE* | 39 | 42 | 2,310 | 3,000 |

| 3 x 35 + 2 x 25/2 + OFE* | 42 | 45 | 2,850 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE* | 46 | 49 | 3,480 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE* | 49 | 52 | 4,380 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 55 | 58 | 5,400 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 58 | 61 | 6,470 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 64 | 67 | 7,850 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 68 | 71 | 9,120 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 73 | 76 | 11,150 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 80 | 84 | 13,490 | 18,000 |

| 8.7/15 (18) kV | ||||

| 3 x 25 + 2 x 25/2 + OFE* | 39 | 42 | 2,310 | 3,000 |

| 3 x 35 + 2 x 25/2 + OFE* | 42 | 45 | 2,850 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE* | 46 | 49 | 3,480 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE* | 49 | 52 | 4,380 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 55 | 58 | 5,400 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 58 | 61 | 6,470 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 64 | 67 | 7,850 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 68 | 71 | 9,120 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 73 | 76 | 11,150 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 80 | 84 | 13,490 | 18,000 |

| 12/20 (24) kV | ||||

| 3 x 25 + 2 x 25/2 + OFE | 46 | 49 | 2,940 | 3,000 |

| 3 x 35 + 2 x 25/2 + OFE | 48 | 51 | 3,340 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE | 50 | 53 | 3,830 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE | 55 | 58 | 4,950 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 58 | 61 | 5,790 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 61 | 64 | 6,820 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 66 | 69 | 8,050 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 70 | 73 | 9,360 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 77 | 80 | 11,200 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 82 | 85 | 13,850 | 18,000 |

| 14/25 (30) kV | ||||

| 3 x 35 + 2 x 25/2 + OFE* | 53 | 56 | 3,880 | 3,000 |

| 3 x 50 + 2 x 25/2 + OFE* | 55 | 58 | 4,390 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE* | 58 | 61 | 5,360 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 62 | 65 | 6,280 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 64 | 67 | 7,160 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 69 | 72 | 8,540 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 73 | 76 | 10,050 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 79 | 82 | 12,150 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 84 | 87 | 14,310 | 18,000 |

| 18/30 (36) kV | ||||

| 3 x 50 + 2 x 25/2 + OFE* | 62 | 65 | 5,210 | 3,000 |

| 3 x 70 + 2 x 35/2 + OFE* | 64 | 67 | 6,030 | 4,200 |

| 3 x 95 + 2 x 50/2 + OFE | 66 | 69 | 6,870 | 5,700 |

| 3 x 120 + 2 x 70/2 + OFE | 69 | 72 | 7,890 | 7,200 |

| 3 x 150 + 2 x 70/2 + OFE | 75 | 78 | 9,320 | 9,000 |

| 3 x 185 + 2 x 95/2 + OFE | 77 | 80 | 10,590 | 11,100 |

| 3 x 240 + 2 x 120/2 + OFE | 85 | 88 | 13,050 | 14,400 |

| 3 x 300 + 2 x 150/2 + OFE | 89 | 93 | 15,230 | 18,000 |